Details

WHAT IS AS/RS?

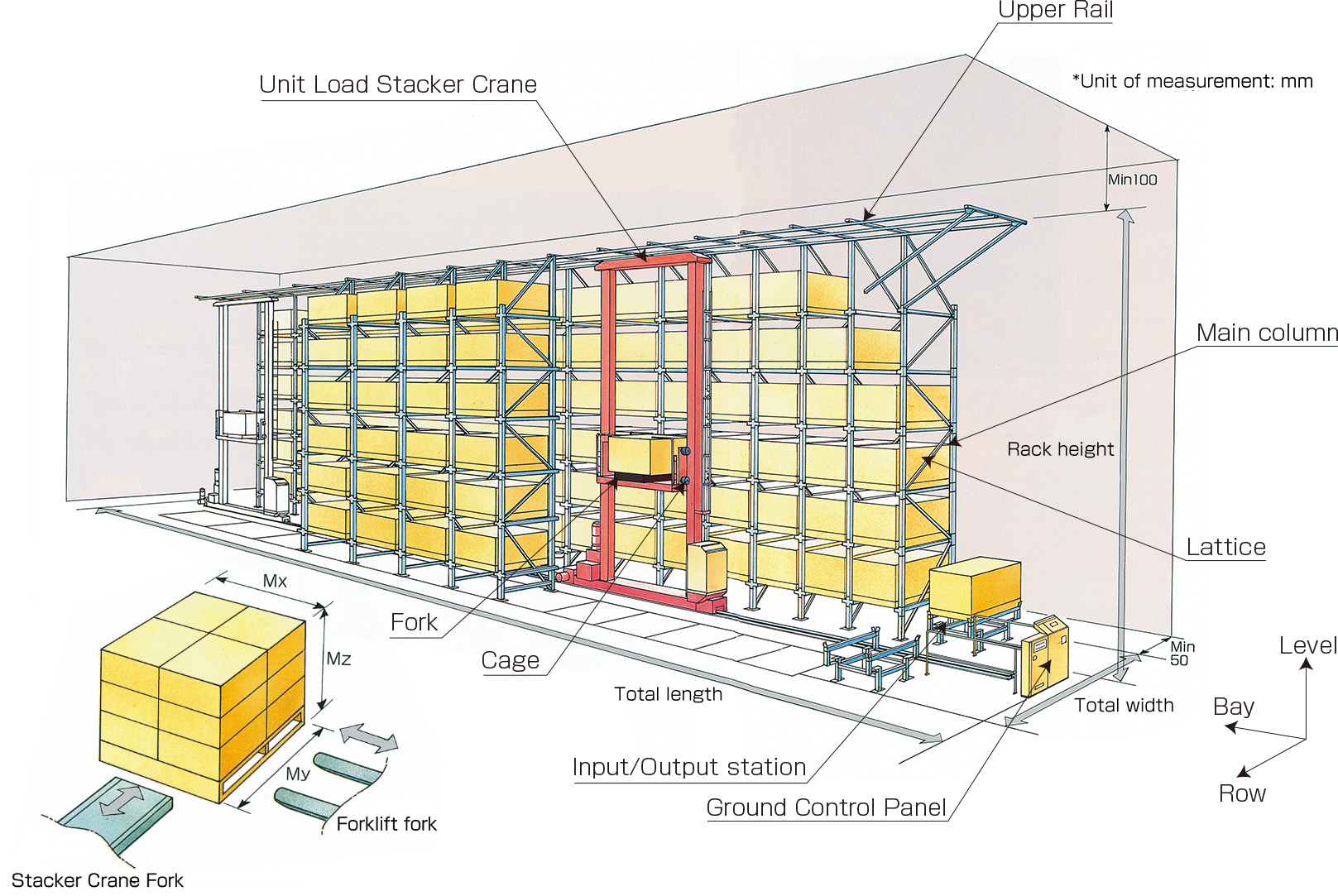

WHAT IS AS/RS?AS/RS (Automated Storage and Retrieval System) refers to a type of inventory management technology used in warehouses, distribution centers, and manufacturing facilities. These systems are designed to efficiently store and retrieve items with minimal human intervention. AS/RS enhances productivity, optimizes space, and reduces labor costs.

Key Components:

- Storage System: Shelves, racks, or bins where items are stored.

- Retrieval System: Mechanisms like shuttles, cranes, or robotic arms to pick or place items.

- Control System: Software and sensors that manage and direct the automated processes.

Types of AS/RS:

- Unit Load AS/RS: Handles large items or pallets.

- Mini-Load AS/RS: Designed for smaller items, usually stored in bins or totes.

- Carousel-based AS/RS:

- Horizontal Carousels: Rotating shelves for picking small to medium items.

- Vertical Carousels: Shelves moving up and down for efficient vertical storage.

- Vertical Lift Modules (VLMs): Automated vertical storage units that deliver items to an operator.

- Shuttle Systems: Robotic shuttles retrieve and deliver items within high-density racks.

Benefits:

- Increased storage density by utilizing vertical space.

- Faster retrieval times and order processing.

- Enhanced accuracy with fewer picking errors.

- Reduced labor costs due to automation.

- Improved safety, as workers are less exposed to hazardous environments.

AS/RS is particularly beneficial in industries like e-commerce, manufacturing, pharmaceuticals, and food and beverage, where efficient inventory management is critical.

View more about AS/RS RACKING SYSTEM on main site